I developed, engineered, and tested new products at Starkey Hearing. As a Mechanical Lead for my project team, I ensured that every part was designed to be robust, reliable, and easy to assemble.

Reinventing Hearing Protection

I served as Mechanical Lead on the team developing the next generation of Starkey’s line of Hearing Protection products. This project has involved every facet of my engineering toolbox:

Designing for micro-injection-molding.

Iterative design in close collaboration with electrical and electroacoustic engineers.

Designing for high-volume assembly.

Constantly looking for opportunities to optimize cycle time, improve reliability, and de-risk the project.

Planning and overseeing Design Verification Testing.

Frequent calls with overseas vendors, ensuring we were aligned on the design intent, and troubleshooting with their engineers when anything went wrong.

My contributions on the project led to a 70% reduction in assembly cycle time and a 50% reduction in BOM cost, beating the cost target by 30%. I look forward to seeing this product hit shelves soon!

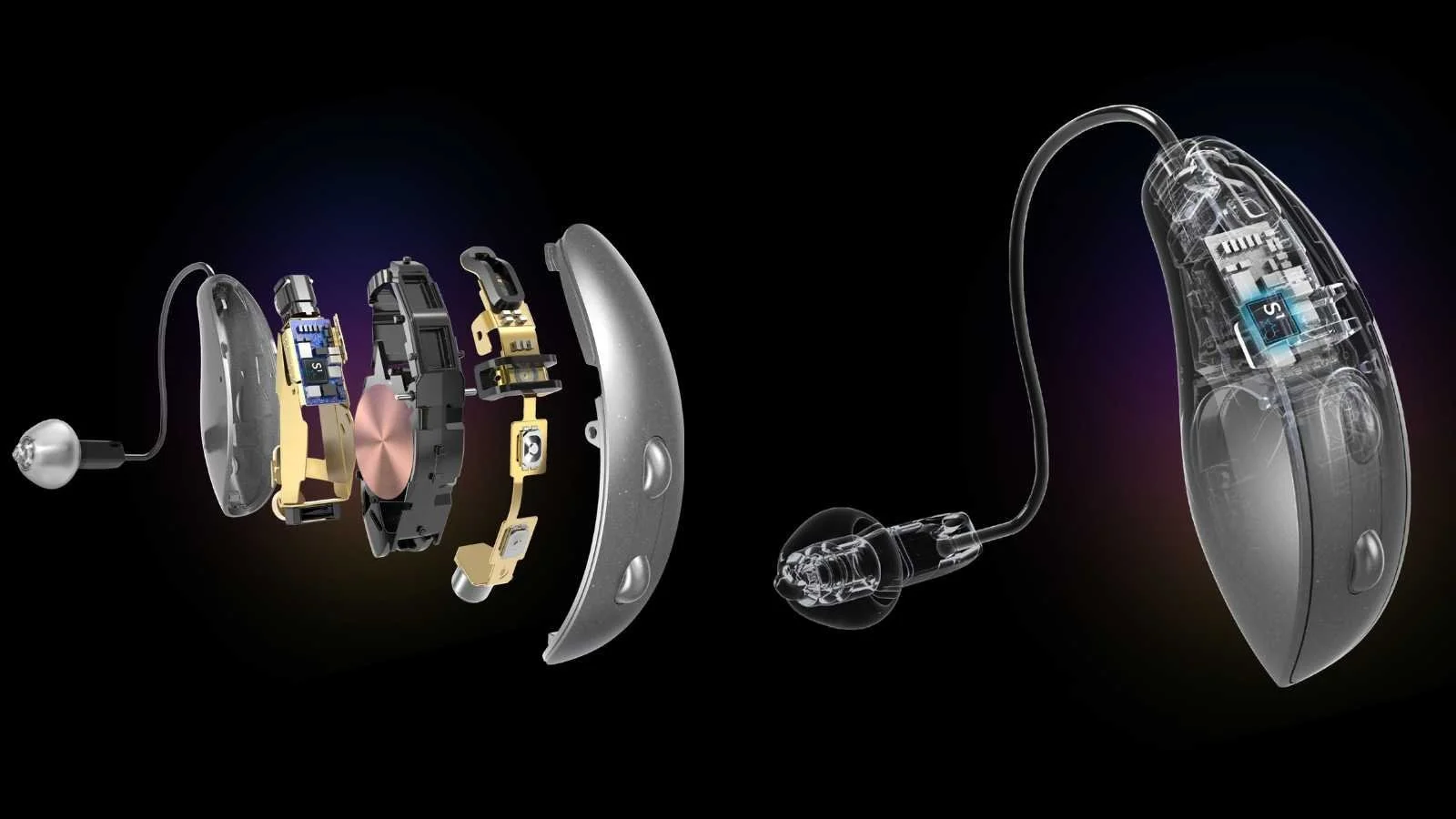

2023 Hearing Aid Launch

I played a key role in stress-testing our newest line of hearing aids, a product line called Genesis AI. I scaled-up a test that had been used to replicate a particular field failure, and then spent 5 months using this system to identify weak-points in our designs. I meticulously removed each layer of protection, learning what could happen if certain assembly steps were skipped, or what could go wrong when coatings inevitably degraded later in the product’s life. My work helped pinpoint key areas to improve, and prove out the efficacy new solutions that the team devised. A year after the launch, we are seeing the results of my work in the form of greatly reduced return rates compared to the old product line.

I also contributed to problem-solving efforts in some of the accessories involved in this launch. An intermittent charging issue was discovered in some pre-production samples of the charger, an issue that the team thought had been resolved earlier in development. I worked closely with our simulations expert, using FEA and tolerance analysis to show that there was a stack-up issue at the heart of this instability. We came up with a design solution that helped short-circuit the tolerance loop, and I invented a special go-gauge to be used at End-of-Line to ensure that the problem never came back again.

Documentation

I was a key contributor to many important types of documentation at Starkey. I wrote test plans and test procedures, drafted and redlined 2D drawings, and created detailed slide decks to report findings to project teams and stakeholders.

Images and video copyright Starkey Hearing 2022-2024